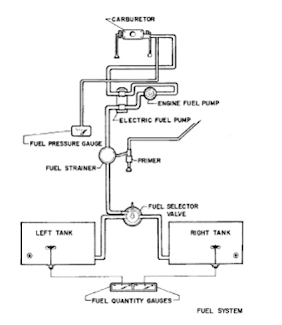

The Fuel System

In an aircraft, many systems work in synergy, but in this

blog post, I will write about issues arising in the fuel system. The fuel

system is designed to deliver an uninterrupted supply of clean fuel from the

fuel tanks to the engine, in a continuous flow. It must be available to the

engine under all situations of engine power, altitude, attitude, and throughout

all allowed flying maneuvers. There are two kinds of fuel systems: the

gravity-feed system, which utilizes the force of gravity to get fuel to the engines;

and the fuel-pump system, in which aircraft have two fuel pumps. In this

system, the main pump system is powered by an engine, with an electrically

powered auxiliary pump available for use during engine startup and in the event

that the engine pump fails.

The

fuel system is composed of different parts, including the fuel primer, fuel

tanks, fuel selectors, fuel gauges, fuel strainers, sumps, and drains. Due to

all of these components, there are many issues that could arise. Engines are

difficult to start in cold weather, therefore the fuel primer comes in handy

since there isn't enough heat sufficient to vaporize the fuel in the

carburetor. When not in use, it is critical to secure the primer. If the knob

is allowed to move during flight, it might vibrate out of place, resulting

in an abnormally rich fuel-air mixture. To avoid this problem (overpriming),

pilots must study the aircraft's priming guidelines. Another issue that can

arise in the fuel system is in the fuel tanks. In order to avoid issues with

fuel tanks, pilots must preform a preflight check including sampling the fuel

from the strainers to see there is no water, settlements, or contaminants, as

well as correct octane (100VLL A VGAS).

In

order to prevent issues with fuel gauges, we must check any result that isn't

"empty" should be double-checked. Pilots should not rely on the fuel

quantity gauges' accuracy alone. During the preflight inspection, pilots

must visually inspect the fuel level in each tank and compare it to the

fuel quantity indication. There's great importance in being through on

preflight fuel checks because there's plenty of evidence that debris (metal

filings, rivets, sealant particles, etc) sneaks into fuel systems, clogging

screens and disrupting normal fuel flow in new installations and, especially,

following repair and maintenance.

It

is also extremely important to drain the fuel strainer before each flight as

well as check for water and contaminants. If in very cold environments the

water in the strainer freezes, it could cause a clog in the fuel lines, leading

to engine failure. In addition, in hot weather, it might pour into the

carburetor and cause the engine to shut down. Finally, we must also be careful

about fuel system icing. This might happen as a result of mechanical agitation

of free water or temperature change of dissolved water. In order to prevent

issues, we can use anti-icing additives that have been approved. However, we

must keep in mind that anti-icing compounds are not a substitute for carburetor

heat.

To conclude, by performing regular maintenance, completing preflight checks, and complying with the airworthiness requirements, we are able to prevent issues in this system.

Resources:

Bingelis, T. (1994). Avoiding Fuel Related Problems. EAA.

Retrieved January 27, 2022, from https://www.eaa.org/eaa/

Federal

Aviation Administration (FAA). (2016). Pilot’s Handbook of Aeronautical

Knowledge (PHAK). Retrieved https://www.faa.gov/

Comments

Post a Comment